3D printing in ceramics made by students

3D ceramics printing business idea has been developed by a group of final year students from the Mechanics Faculty of the Da Nang University of Science and Technology. They are Nguyen Thanh Do, Nguyen Van Dung, and Doan Cong Trung.

|

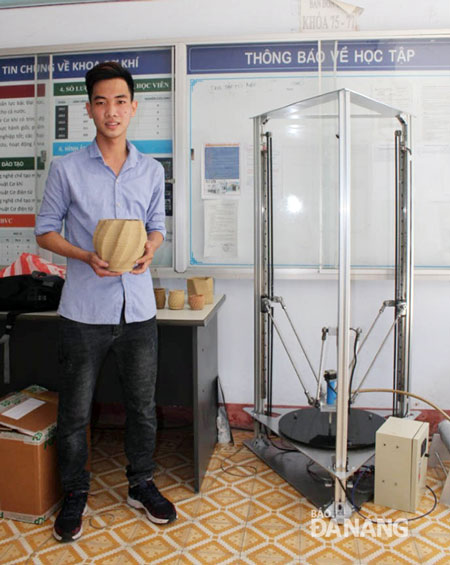

| Nguyen Thanh Do and his group's creations |

Their product won first prizes in the university’s science research contest. It boasts its creativeness and high applicability.

The idea to create the printer came from the popularity of 3D printing technology worldwide, but the technology remains uncommon in Viet Nam because 3D printing machines are very expensive.

In addition, when visiting Hoi An City in Quang Nam Province, Thanh Do realised that traditional ceramic villages are facing a lack of human resources. This inspired him and some of his classmates to join forces to create a 3D ceramic printer to make tableware.

It took these talented students 9 months to develop their new product.

The delta-style ceramic 3D printer is the same height as an adult. It is connected with a laptop, an air compressor, and refueling equipment.

The extrusion mechanism is located above the printing platform and this, therefore, enables printing directly from the end of the extruder tip.

The printer can produce clay creations such as beautiful vases and teacups with maximum height of 6cm and maximum diameter of 30cm. The products are, then, baked at the Thanh Ha traditional ceramic village in Hoi An City.

Do remarked that making print heads and processing raw clay materials have taken them a lot of time and effort.

He added that print heads are considered as the soul of the machine, and each of them is being sold at the price of up to thousands of euro in European countries. Therefore, Do and his friends have done their utmost to create print heads at very reasonable prices which still meet the requirements for the operation of the 3D printer.

Dr Le Hoai Nam, the Deputy Dean of the University’s Mechanics Faculty, highlighted the advantages of his students’ product which can produce clay creations with complex shapes.

Do added that he and other his group members would perfect their printer’s design, and they hoped they would develop their ideas for future startup business.